principle of operation

Metering pumps are positive displacement pumps which is designed to pump at constant flow rates against a wide range of discharge pressure, including high discharge pressures of tens of bar. When the cam moves backward, a vacuum is created. An exactly defined volume of liquid is drawn into the displacement body on the reciprocal stroke and forced into the dosing line on the compression stroke.

The advantage of these types of pumps lie in that outside influences does not change volume set to be dosed. Thus having varying pressures and varying mainline flows, does not influence the set dosed volume.

ACCURACy and simplicity in function

Tens of thousands of our pumps are in use all over the globe, delivering reliable, accurate performance under the toughest conditions. Our proven design principles guarantee a high standard of quality and precision.

The product range

Large choice of types, wide range of capacities: from a few ml, e. g. for chlorination and acid use, to 5000 l/h, e. g. for use in process engineering and agriculture.

The technologies in detail:

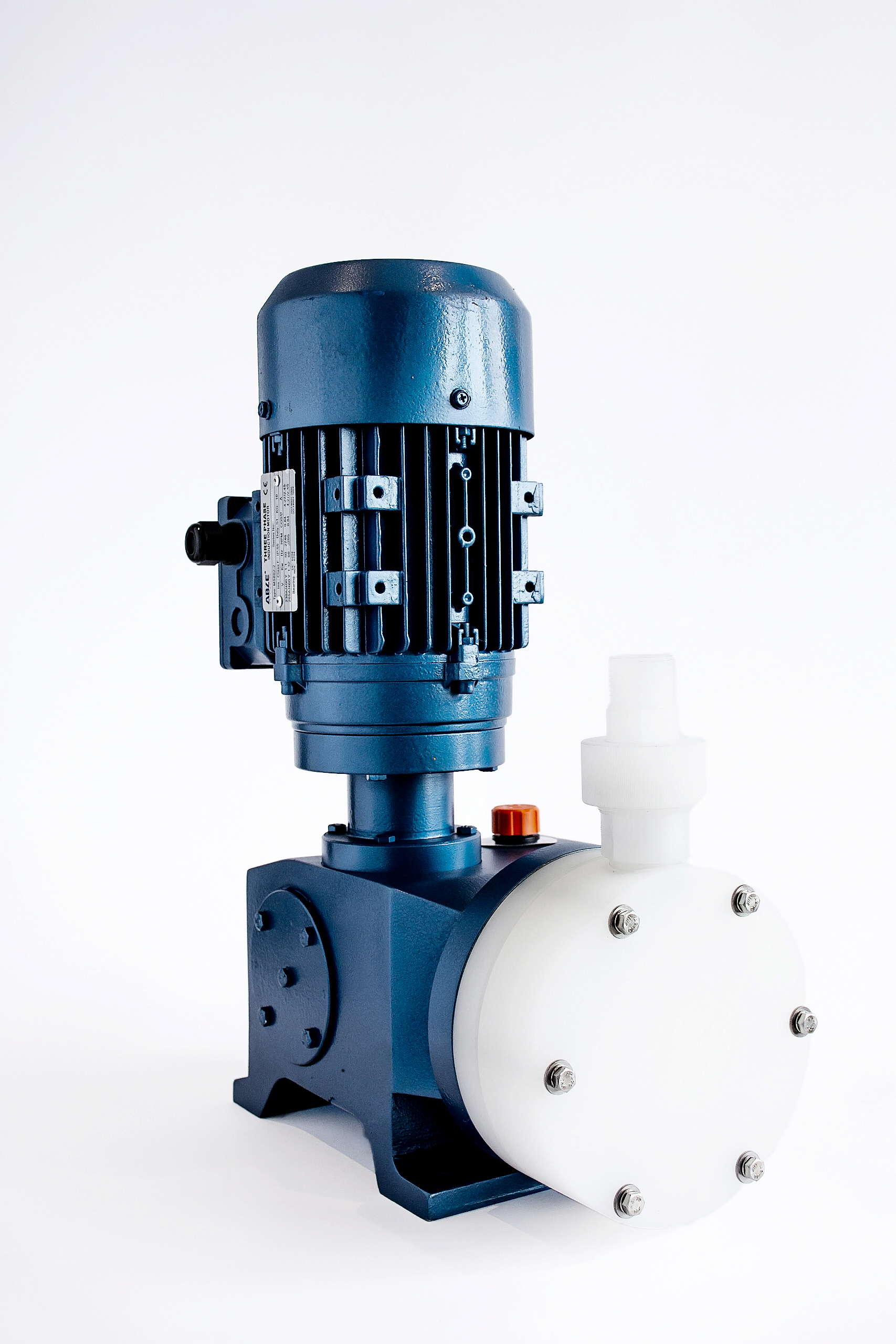

Diaphragm metering pumps (mechanically deflected diaphragm)

Hydraulic diaphragm metering pumps (hydraulically deflected diaphragm)

Plunger metering pumps

Solenoid driven metering pumps

Electronically controlled metering pumps

Classification by pump drive:

Solenoid-driven metering pumps

Motor-driven metering pumps

Find the right pump type with these steps:

Specify end-result required by using dosing pump

Specify product to be dosed

Specify sg of product

Specify volume of product to be dosed

Specify pump capacity in litres per hour [l/h]

Specify back pressure in bar

Find the intersection of these two values and select the pump model closest

Specify power supply

If pump capacity is unknown, our experts would be able to determine capacity according to product requirement needs per unit of dosage.